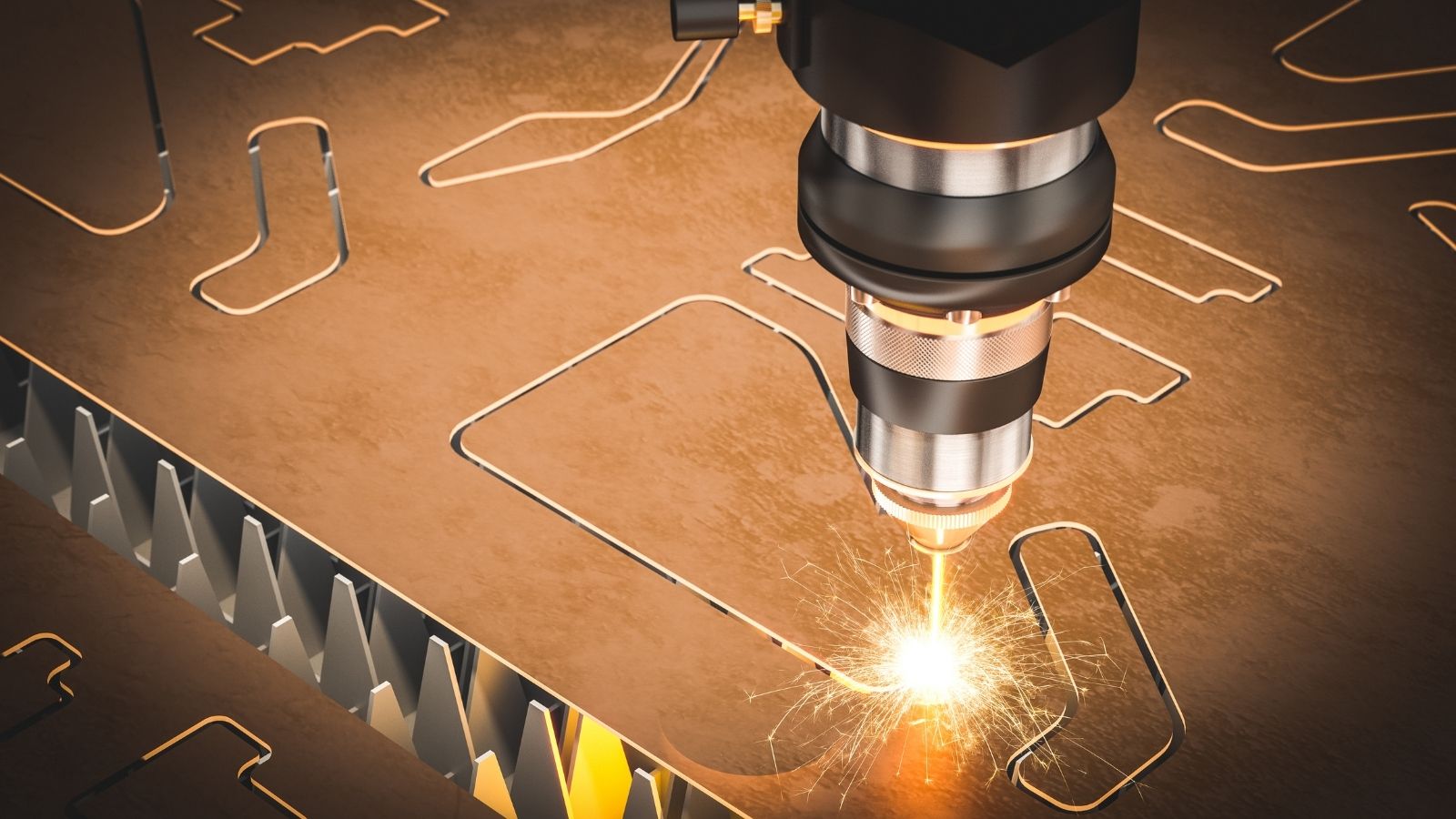

CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

CNC machining is a type of manufacturing that uses computer-controlled tools to create parts and components. It is a versatile process that can be used to produce a wide variety of parts, from simple to complex.

CNC machining is particularly well-suited for small batch production. Here are some of the benefits of using CNC machining for small batch production:

• Accuracy: CNC machining is a very accurate process, which is essential for small batch production. When parts are produced in small batches, it is important to ensure that they are all of the same quality and precision. CNC machining can help to ensure that this is the case.

• Repeatability: CNC machining is a repeatable process, which means that the same part can be produced over and over again with the same results. This is important for small batch production, as it allows businesses to produce parts that meet the same specifications.

• Flexibility: CNC machining is a flexible process, which means that it can be used to produce a wide variety of parts. This makes it a good choice for businesses that need to produce a variety of small batch parts.

• Efficiency: CNC machining is an efficient process, which can help businesses to reduce costs. CNC machines can operate for long periods of time without the need for human intervention, which can free up workers to focus on other tasks.

In addition to these benefits, CNC machining can also help businesses to improve their quality control, reduce waste, and meet customer demands.

Here are some specific examples of how CNC machining can be used for small batch production:

• Custom parts: CNC machining can be used to produce custom parts that meet the specific needs of a business or customer. This can be a great way to differentiate a business from its competitors.

• Prototypes: CNC machining can be used to quickly and easily produce prototypes of new products. This can help businesses to reduce the time and cost of bringing new products to market.

• Repairs and maintenance: CNC machining can be used to repair or refurbish existing parts. This can save businesses money on the cost of replacement parts.

Selecting the appropriate material for CNC machine tool low-volume projects is crucial for achieving the desired performance, aesthetics, and cost-effectiveness. The choice of material depends on several factors, including the specific application, desired properties, and production volume.Selecting the appropriate material for CNC machine tool low-volume projects is crucial for achieving the desired performance, aesthetics, and cost-effectiveness. The choice of material depends on several factors, including the specific application, desired properties, and production volume.

Common Materials for CNC Machining

• Aluminum: Aluminum is a lightweight, strong, and corrosion-resistant metal that is widely used for CNC machining. It offers excellent machinability, producing a smooth finish and tight tolerances. Aluminum is a good choice for applications that require a balance of strength, weight, and corrosion resistance, such as aerospace components, electronic enclosures, and automotive parts.

• Stainless Steel: Stainless steel is a versatile material known for its exceptional corrosion resistance and durability. It is available in various grades with different properties, ranging from soft and machinable to hard and wear-resistant. Stainless steel is often used for medical devices, food processing equipment, and tools that require high strength and resistance to corrosive environments.

• Carbon Steel: Carbon steel is a common and cost-effective material with good strength, ductility, and machinability. It is available in a range of carbon content, affecting its hardness and strength. Carbon steel is suitable for various applications, including structural components, machine parts, and tools that require moderate strength and affordability.

• Brass: Brass is a copper-zinc alloy that offers a combination of corrosion resistance, machinability, and good electrical conductivity. It is often used for ornamental parts, fixtures, and components that require a combination of aesthetics, functionality, and ease of machining.

• Plastics: Plastics are lightweight, versatile, and cost-effective materials that offer a wide range of properties, including flexibility, impact resistance, and electrical insulation. Common plastics for CNC machining include acrylic, polycarbonate, ABS, and nylon. Plastics are suitable for applications that require non-metallic materials with specific properties, such as enclosures, prototypes, and components that require lightweight construction.

• Low-volume CNC machining is a versatile manufacturing technique that is well-suited for producing small quantities of precision parts. It offers several advantages over traditional manufacturing methods, making it a popular choice for a wide range of applications.

• Common Applications for Low-Volume CNC Machined Parts:

• Prototyping: CNC machining is an ideal method for creating prototypes for new products. It allows for rapid iteration and design changes, enabling businesses to quickly refine their designs before committing to mass production.

• Custom Parts: CNC machining can produce custom parts that meet specific requirements and specifications. This is particularly useful for applications where standard parts are not available or where unique designs are needed.

• Replacement Parts: CNC machining can be used to manufacture replacement parts for existing equipment or machinery. This can help extend the lifespan of equipment and reduce downtime.

• Medical Devices: CNC machining is widely used in the medical industry to produce precise and biocompatible components for medical devices, implants, and surgical instruments.

• Aerospace Components: CNC machining is essential for manufacturing high-performance aerospace components that demand extreme precision, strength, and lightweight construction.

• Electronic Enclosures: CNC machining is used to create precision enclosures for electronic devices, ensuring compatibility, protection, and aesthetic appeal.

• Tooling and Fixtures: CNC machining is employed to produce custom tooling and fixtures that are vital for manufacturing processes in various industries.

• Artistic and Decorative Pieces: CNC machining can be used to create intricate and personalized artistic pieces, such as sculptures, jewelry, and decorative elements.

• Educational and Research Applications: CNC machining is valuable for educational and research purposes, allowing students and researchers to explore design concepts and test material properties.

• Repair and Refurbishment: CNC machining can be used to repair or refurbish damaged or worn-out components, extending their service life and reducing the need for replacements.

Small batch CNC processing can effectively reduce costs and better change designs. The general production quantity is between 10-1000. If you would like to know more please contact us for more information.