CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

JM Precision provides a complete set of services from mold design, mold production to product mass production, which can be used for hand board and small batch to large batch production. Fast response.

Get A quoteAdopt ISO9001,AS9100D

Equal quality system certification

On-demand Production On-time Delivery High Quality & Services

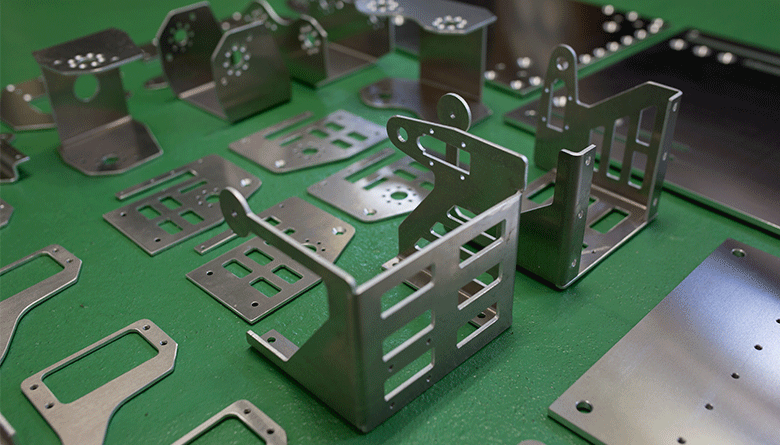

Sheet metal is a comprehensive cold working process for sheet metal (usually less than 6mm), including shearing, punching / cutting / compounding, folding, riveting, splicing, forming (such as automobile body), etc. Its remarkable feature is that the thickness of the same part is the same.

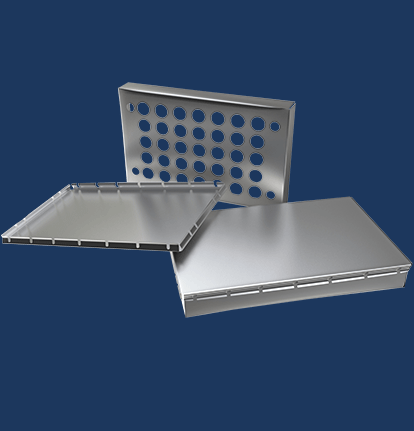

JM Precision has complete sheet metal processing equipment: punch, bending machine, EDM, grinder, etc., covering plate cutting, stamping, laser cutting, crimping, bending, ironing, welding and other processing processes, which can meet customers' various sheet metal processing needs.

It is a common sheet metal forming process. Punch and die group are used to punch holes in sheet metal. During machining, the sheet metal is placed between the punch and the die, and then the punch is pressed down and passes through the sheet metal, thus completing the punching process.

Get A quote

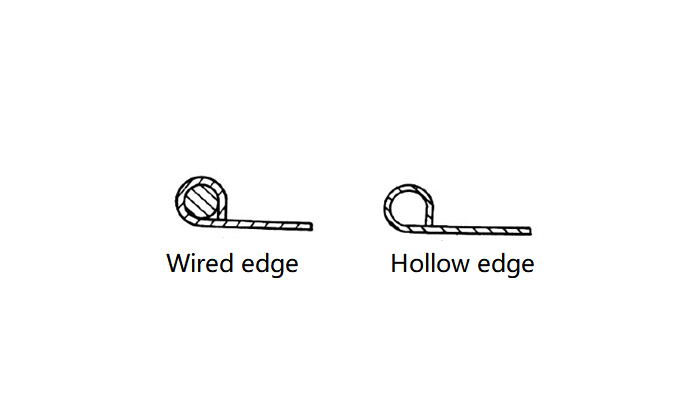

It is a sheet metal forming process. After the initial production of sheet metal, there are usually sharp edges with "burrs". The purpose of crimping is to smooth the sharp and rough sheet metal edges to meet the use requirements of the project.

Get A quote

It is another common sheet metal forming process. Manufacturers usually use brake press or similar mechanical press for metal bending. The sheet metal is placed on the die, and the punch is pressed down on the sheet metal. The huge pressure makes the sheet metal bend.

Get A quote

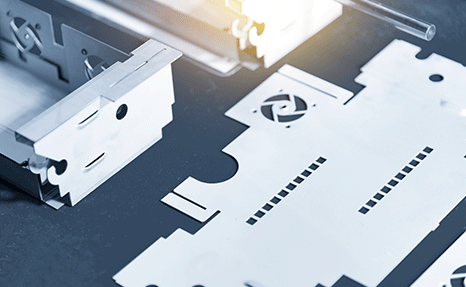

Laser cutting has become a more and more common sheet metal forming process. When the sheet metal is exposed to high power and high density laser, the heat of the laser melts or vaporizes the sheet metal in contact with it, forming a cutting process. This is a faster and more accurate cutting method, which is automatically executed by computer numerical control (CNC) laser cutting machine.

Get A quoteSheet metal has the characteristics of light weight, high strength, conductivity (can be used for electromagnetic shielding), low cost and good mass production performance.

It plays an important role in construction and manufacturing industry. In the construction industry, it is used as a building and shell or roof; In the manufacturing industry, sheet metal has been widely used in electronic and electrical appliances, communication, automobile industry, medical devices and other fields. For example, sheet metal is an essential part in computer chassis, mobile phone and MP3. With the more and more extensive application of sheet metal, the design of sheet metal parts has become a very important part in the process of product development.

Mechanical engineers must master the design skills of sheet metal parts, so that the designed sheet metal can not only meet the requirements of product function and appearance, but also make the manufacturing of stamping die simple and low cost.

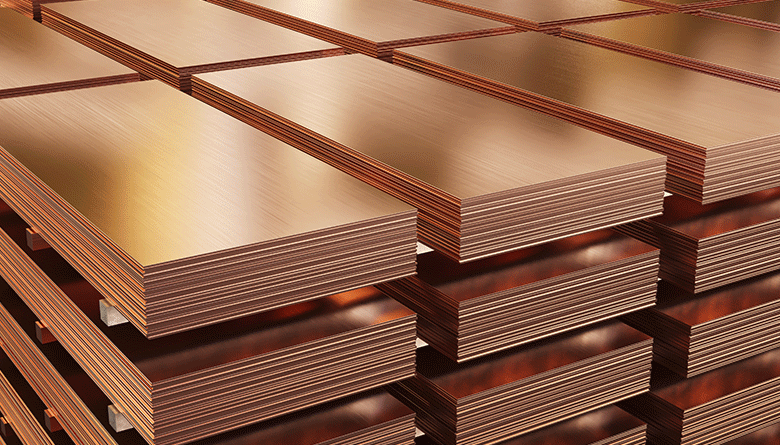

Sheet Metal Processing have a long list of available materials for prototypes and manufacturing parts, from hard metals like stainless steel and carbon steel, to soft metals such as aluminum, copper, brass.

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio, low cost, and recyclability. Jinming offers multiple aluminum alloys such as 2024, 5052, 6061, 6063, 7050, 7075 and so on, as a high-quality silver metal that’s soft, lightweight and durable, it is commonly used for 5-axis CNC machining in and aerospace applications.

Stainless steel is highly resistant to corrosion and rust, making it a popular industrial alloy used in a wide variety of industries. Stainless steel is used to manufacture handles, medical devices, lab instruments, automotive parts, weld ferrules, and more. Jinming offers multiple stainless steel such as 303,304, 316,17-4PH, 4130, 4140 and so on.

Brass is a metal alloy made of copper and zinc, brass has decent strength, electrical conductivity, and minimal tool wear. It is commonly used for a variety of parts such as gears, lock components, pipe fittings, and ornamental applications.

Bronze is an alloy comprised of copper and tin, and it offers a wide range of properties such as good wear and corrosion resistance, high ductility, hardness, thermal conductivity and strength. Bronze is often used to manufacture nuts, bolts, threaded parts, bearings, bushings, screws, and more.

Copper is a common metal offering excellent thermal and electrical conductivity, which make them natural choices for wiring, motors and other electrical applications.

Carbon Steel is a iron carbon alloy containing 0.0218% to 2.2.11% carbon. In general, the higher the carbon steel, the higher the hardness, the higher the strength, but the plasticity is low. Carbon steel is usually used in mechanical parts such as auto parts, nuts, gears. Jing Ming offers a variety of carbon steel, such as Q235, SPCC, SECC etc.

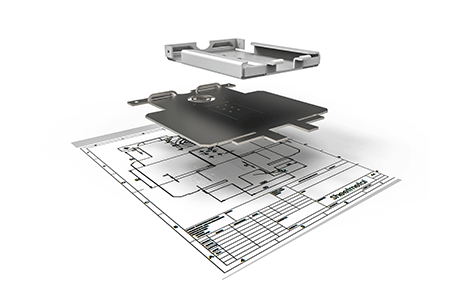

Our basic guidelines for sheet metal fabrication include important design considerations to help improve part

manufacturability, enhance cosmetic appearance, and reduce overall production time.

Maximum Dimensions

| SIZE | 36 in. x 48 in. |

|---|---|

| BEND LENGTH | 96 in. |

Maximum Dimensions

| FLAT PART | 0.5 in. x 0.5 in. |

|---|---|

| FORMED PART | 1.5 in. x 1.5 in. |

Single Surface

| BENDS | +/- 1 degree |

|---|---|

| OFFSETS | +/- 0.012 in. |

| HOLE DIAMETERS | +/- 0.005 in. |

| HARDWARE TO HARDWARE | +/- 0.005 in. |

| HARDWARE TO EDGE/HOLE | +/- 0.010 in. |

| BEND TO EDGE | +/- 0.015 in. |

Tolerances vary on depending on part feature

such as bends, offsets, holes, and inserted hardware.

We have various equipment including punch, bending machine, wire EDM, grinder etc. covering all machining process like cutting, punching, laser cutting, crimping, bending, ironing & pressing, welding etc.

We have 10+ years experienced skillful engineering team, who can not only meet the feature and outlook requirement, but also make mould simple and cost effective.

We have obtained ISO9001, AS9100D management system certificate, and have a professional quality management team with more than 50+ staff, we achieve DMMP 500, so our product quality is guaranteed.

Rapid customer service, we provide technical support before sales, and guarantee delivery after confirm order, on time delivery rate is 99%.

JM Precision sheet metal processing covers various processes such as cutting, stamping, laser cutting, crimping, bending, ironing and welding. It can be used for hand board and small to large-scale production, and can meet various sheet metal processing needs of customers. The following processing cases are for your reference. If you have any questions or needs, you can contact us at any time.

| Part | Size | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|---|

| Pedal | 212*135*3mm | Aircraft seat | Stamping / bending | 2017A-T4 Aluminum | - |

| Outer cover | 150*60*1mm | Digital camera | stamping | 6061-T6 Aluminum | - |

| Support frame | 220*100*2mm | Welding machine | Bend | SPCC | - |

Our products are distributed in more than 20 countries, and we have won high praises from many

worldwide famous big customers by our exquisite craftsmanship, high efficiency and excellent customer services.

A whole set of services from design, prototype, CNC machining, sheet metal & mould, painting, powder coating and assembly.

Strict quality control system, successfully obtained many international certifications: AS9100D,ISO9001, ISO14001, NADCAP. Achieve DPPM 500.

We have automatic intelligent equipment like Swiss ABB robot arm which can save time and labour cost, thus improving the efficiency.

10+ years experience and skillful engineers team, pursue excellence and innovation, improve efficiency and high-end product supply capacity.the fastest delivery within 3 days.