CNC Machining

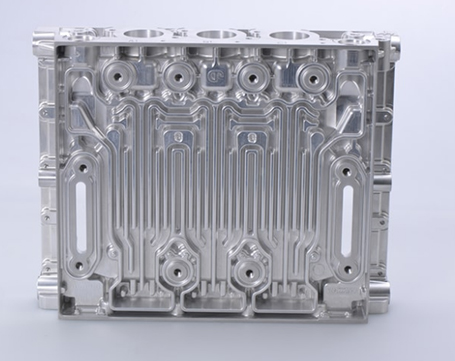

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

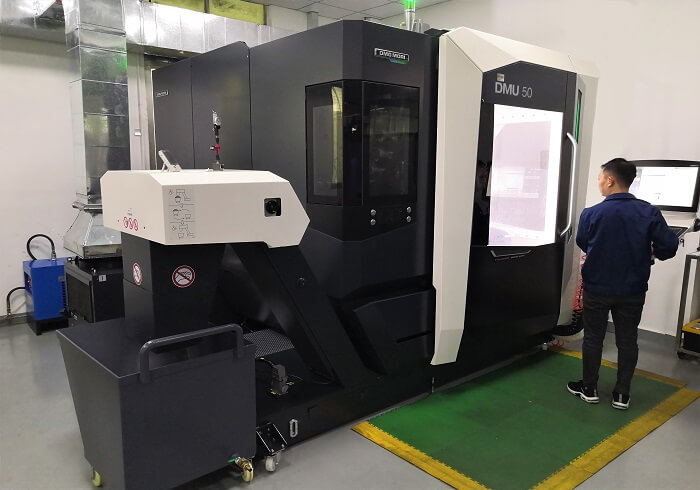

Advanced DMG 5 Axis CNC Machine

Skilled And Experienced Programmers

High Precision, Accuracy, Complexity

On Time Delivery

Adopt ISO9001,AS9100D

Quality system certification

Workshop

CNC machines

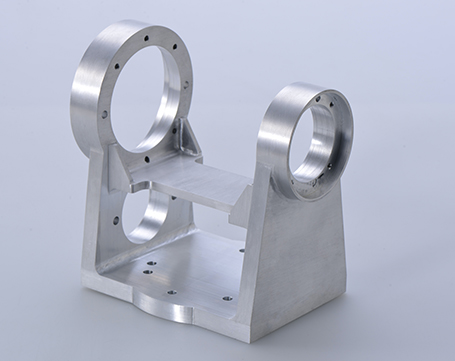

Plastic and metal materials

JM Precision has more than 10 years of experience in the machining industry, with a variety of equipment and complete processes: there are three-axis, four-axis, Germany DMG brand and US Haas brand five-axis machining centers, Japanese TSUGAMI brand CNC lathes and turn-milling CNC machining centers , covering turning, drilling, milling, broaching, grinding, EDM and other machining processes, so as to provide customers with excellent services.

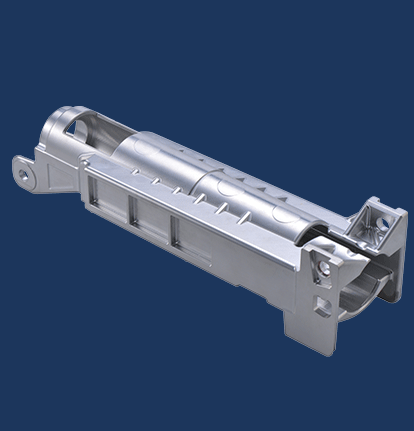

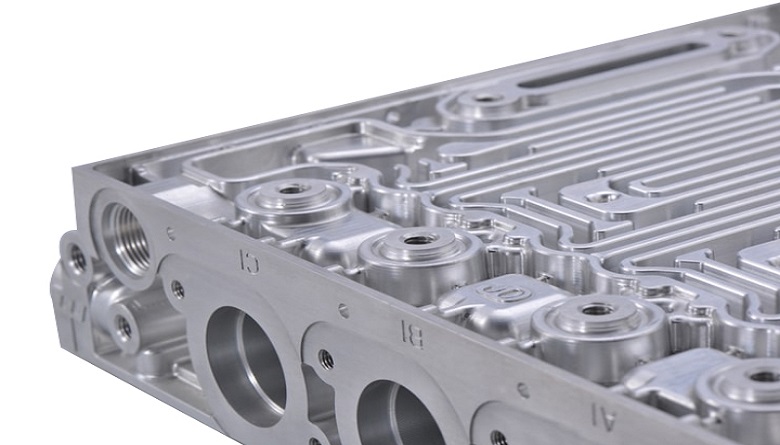

Boring And Milling

CNC Turning

Five axis

Machining Center

Turn-milling

CNC Machining

Center

Boring and milling machining center is the first developed and most used machining center at present, so the commonly called machining center generally refers to boring and milling machining center. Its main process capability is mainly boring and milling, and it can also carry out drilling, expanding, reaming, spot facing, tapping and other processing.

The machining objects mainly include: plane parts with a fixed angle (constant) between the machining surface and the horizontal plane, such as disc, sleeve and plate parts; Variable angle parts with continuous change of the included angle between the machining surface and the horizontal plane; Box parts; Complex curved surface (CAM, integral impeller, mold, spherical surface, etc.); The shape of special-shaped parts is irregular, and most of them need multi station mixed processing of point, line and surface).

JM Precision has around 200 sets of 3-axis, 4-axis and 5-axis machining centers with an accuracy of 0.0004 '' (0.01mm).

On the basis of NC lathe, turning is equipped with tool magazine and manipulator to greatly increase the number of tools that can be selected. The turning center mainly focuses on turning, and can also process milling, drilling, expanding, reaming, tapping and so on. Its machining objects mainly include: conical surface of complex parts and rotating body with complex curve as bus. On the turning center, it can also drill radial holes, mill keyways, mill cam grooves and spiral grooves, taper threads and variable pitch threads. Turning centers generally also have the following two advanced functions.

1) The function of power tool is that some or all tool positions on the tool holder can use rotary tools (such as milling cutter and drill bit) to rotate these tools through the power in the tool holder.

2) The c-axis position control function can realize the arbitrary position control of the spindle in the circumferential direction. Realize x-C and z-c linkage. In addition,some turning centers also have Y-axis function.

JM Precision has a number of advanced CNC lathes with an accuracy of 0.0002''(5um). Professional technical team and quality management system fully guarantee the quality and delivery of customers

In addition to the functions of general machining centers, the biggest feature of the five axis machining center is that it has a spindle head that can be converted vertically and horizontally. With the support of NC indexing worktable or NC rotary worktable, it can realize one-time clamping of hexahedral parts (such as box parts) and machining of five faces. This kind of machining center can not only greatly reduce the auxiliary time of machining, but also reduce the influence of positioning error due to multiple clamping on the accuracy of parts.

JM Precision has Germany DMG brand and American Haas brand 5-axis CNC center, with an accuracy of 0.0004 '' (0.01mm). It can reduce fixture preparation to save time and cost. When machining complex shapes, it only needs one setting to improve productivity. Shorter cutting tools can be used to produce higher cutting speed and less tool vibration to obtain higher precision. It can also achieve excellent surface finish to improve the overall part quality.

As the name suggests, turn-milling compound processing equipment refers to the processing equipment with both turning function and milling function. In this sense, the above turning center also belongs to this type of processing equipment. However, what is said here generally refers to the large and heavy turn milling composite processing equipment, in which the turn and milling functions are equally powerful, which can realize the processing of multiple surfaces in one clamping of some large and complex parts (such as the integral propeller for large ships), so as to improve the machining accuracy of the part surface and the mutual position accuracy of each machining surface (such as the mutual position accuracy of propeller blade profile, positioning hole, installation positioning surface, etc.) is guaranteed by the accuracy of the equipment.

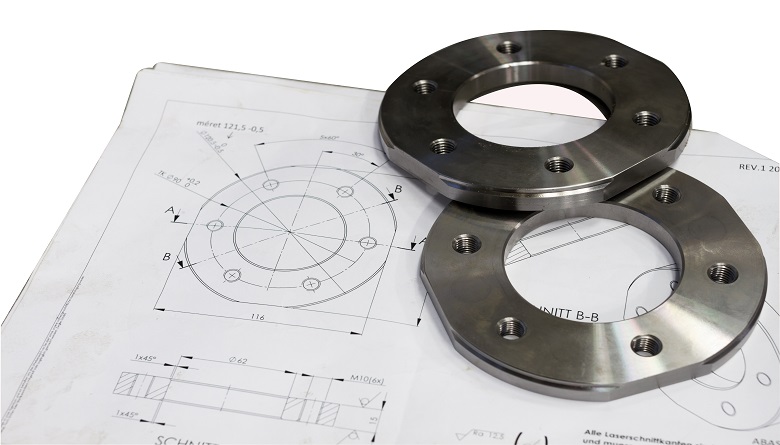

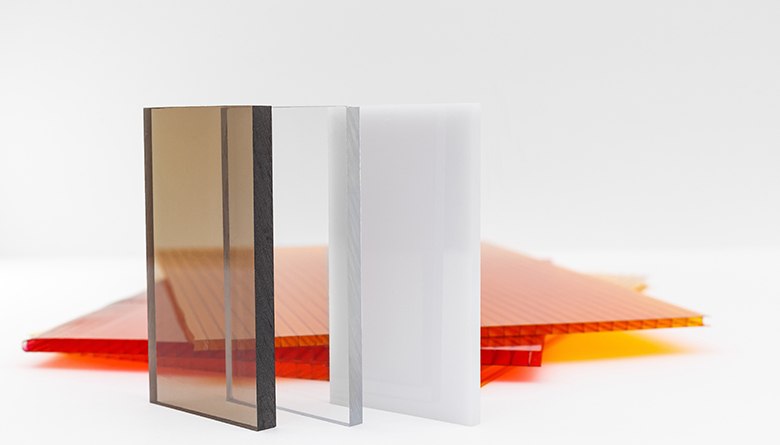

CNC machining have a long list of available materials for CNC prototypes and manufacturing parts, from hard metals like stainless steel and titanium, to soft metals such as aluminum, copper, brass, all the way to plastics including ABS, PC, PA,etc.

Metal

Plastic

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio, low cost, and recyclability. Jinming offers multiple aluminum alloys such as 2024, 5052, 6061, 6063, 7050, 7075 and so on, as a high-quality silver metal that’s soft, lightweight and durable, it is commonly used for 5-axis CNC machining in and aerospace applications.

Stainless steel is highly resistant to corrosion and rust, making it a popular industrial alloy used in a wide variety of industries. Stainless steel is used to manufacture handles, medical devices, lab instruments, automotive parts, weld ferrules, and more. Jinming offers multiple stainless steel such as 303,304, 316,17-4PH, 4130, 4140 and so on.

Brass is a metal alloy made of copper and zinc, brass has decent strength, electrical conductivity, and minimal tool wear. It is commonly used for a variety of parts such as gears, lock components, pipe fittings, and ornamental applications.

Bronze is an alloy comprised of copper and tin, and it offers a wide range of properties such as good wear and corrosion resistance, high ductility, hardness, thermal conductivity and strength. Bronze is often used to manufacture nuts, bolts, threaded parts, bearings, bushings, screws, and more.

Copper is a common metal offering excellent thermal and electrical conductivity, which make them natural choices for wiring, motors and other electrical applications.

Cast iron is a dependable wear-resistant material which machines faster than many steel varieties. This is an ideal material for absorbing vibrations. Parts commonly made with cast iron include gears, bases, pulleys and bushings.

Titanium is an element alloyed with iron, aluminum, vanadium, and molybdenum, with good corrosion resistance and the ability to be welded. Common use cases include aerospace fasteners, turbine blades, engine components, sports equipment and marine applications.

Hastelloy is a strong nickel-chromium-iron-molybdenum alloy resistant to corrosion. Hastelloy steel is often used to manufacture contour rings, rings, hubs, flanges, shafts, and other manufactured products.

ABS is a low-cost engineering plastic, widely used for pre-injection molding prototypes. CNC machined ABS is a great option for production-like parts, where detail and mechanical properties are important.

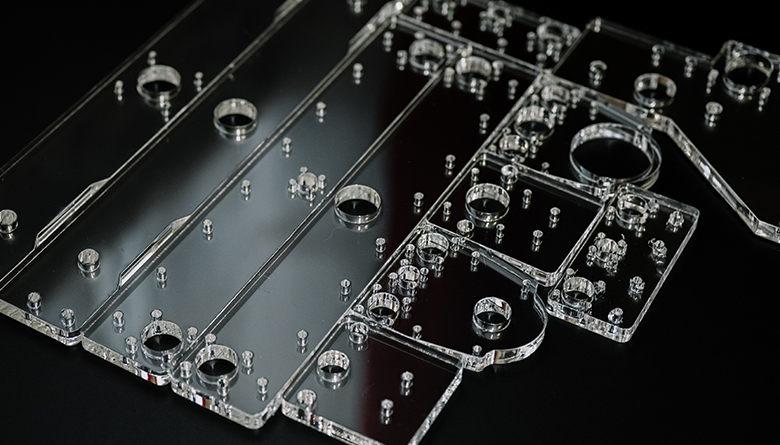

Acrylic is known as PMMA, an abbreviation of its full chemical name, polymethyl methacrylate. It is a scratch-resistant plastic, available optically clear or opaque. It is often used for tanks, panels, and optical applications. It can be somewhat brittle in thin walled areas, so it is not recommended for delicate or complex geometries.

Polycarbonate (known also by the abbreviation PC) is one of the most common plastics used in manufacturing.

It is heat-resistant, impact-resistant, flame-retardant, and one of the most recycled plastics in the world. Famous examples of the material are first-generation MacBook laptops, safety goggles, and optical disks.

Polyphenylene Sulfide (PPS) is a high-performance engineering plastic with excellent temperature resistance, dimensional stability, and electrical insulation properties. With exceptional mechanical strength, chemical resistance, and flame resistance, PPS is commonly found in high temperature applications such as automotive parts, appliances, electronics, medical devices, and industrial applications.

Delrin (generic: acetal) is a low-friction, high-stiffness material, with a relatively high toughness and minimal elongation, Delrin boasts excellent dimensional accuracy. It is used in applications ranging from auto parts to musical instruments.

In high-stress/high-temperature applications, PEEK is a great lightweight substitute for most soft metals. Additionally, PEEK is resistant to moisture, wear, and chemicals. Glass-filled PEEK is a high performance plastic with excellent rigidity, strength and toughness. The addition of glass fibers enhances its ability to maintain dimensional stability even in harsh thermal and chemical environments. This material is often used in the following industries: aircraft, automotive, medical, chemical and microwave.

Garolite(also known as phenolic and epoxy-grade industrial laminate) is a composite material with a low coefficient of thermal expansion. Additionally, it does not absorb water and is an excellent insulator, which makes it really useful for electronics applications.

We have advanced high precision equipment like Germany DMG 5 axis machine, US Haas 5 axis machine, tolerance down to +/-0.0004’’(0.01mm).

We have 10+ years experienced skillful engineering team, pursue excellence and technical innovation.

We have automatic intelligent equipment like Swiss ABB robot arm which can save time and labour cost, thus improving the efficiency.

We have obtained ISO9001, AS9100D management system certificate, and have a professional quality management team with more than 50+ staff, we achieve DPPM 500, so our product quality is guaranteed.

JM Precision CNC processes all kinds of turning, drilling, milling, broaching and grinding parts, provides uncalibrated and customized services for processing parts in all walks of life, and has rich experience in processing parts with complex shape and high precision requirements. The following processing cases are for your reference. If you have any questions or needs, you can contact us at any time.

| Part | Size | Application | Machining Process Used | Material | Specific Feature |

|---|---|---|---|---|---|

| Outer plate | 605*390*25mm | Business class seats | Three axis milling | 6061-T651 Aluminum |

The inner wall is thin and easy to deform |

| Upper bracket | 420*300*40mm | Aircraft kitchen | Four axis milling | 7075-T6511 Aluminum | Complex structure |

| Hinge | 80*21.5*12.5mm | Aircraft cabinet door hinge | Four axis milling | 304L Stainless Steel | Concentricity 0.02 |

| Scroll frame | 150*80*30mm | manipulator | Five axis milling | 2024-T651 Aluminum |

The inner wall is thin and easy to deform |

| Cutter head | D26*15mm | Scalpel |

Turn milling compound machining |

316 Stainless Steel |

The knife edge shall be sharp |

Our products are distributed in more than 20 countries, and we have won high praises from many

worldwide famous big customers by our exquisite craftsmanship, high efficiency and excellent customer services.

A whole set of services from design, prototype, CNC machining, sheet metal & mould, painting, powder coating and assembly.

Strict quality control system, successfully obtained many international certifications: AS9100D,ISO9001, ISO14001, NADCAP. Achieve DMMP 500.

Advanced equipment, automated & intelligent production improve the quality and capacity: Germany DMG, US Haas CNC machines, Japan TSUGAMI lathe, Swiss ABB brand robot arm, ZEISS CMM.

10+ years experience and skillful engineers team, pursue excellence and innovation, improve efficiency and high-end product supply capacity. the fastest delivery within 3 days.