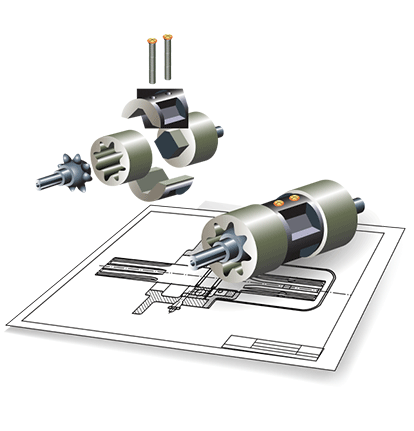

CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

Constant temperature and humidity clean assembly workshop

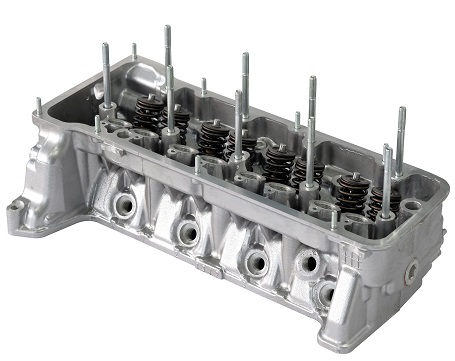

Batch management of core parts

ERP,MES management system and code scanning technology are adopted

Effectively ensure product traceability

Get A quote

The assembly workshop shall meet the requirements of constant temperature, humidity and clean environment, strictly implement the assembly operation procedure (SOP) of clean room, and specify the training contents,requirements for purified clothes, indoor air quality standards,records,conventional working conditions and operating procedures.

ERP, MES management system and code scanning technology are adopted to effectively ensure the traceability of products.

In engineering structures, two or more parts or components are connected as a whole by bolts, which is mostly used in steel structures.

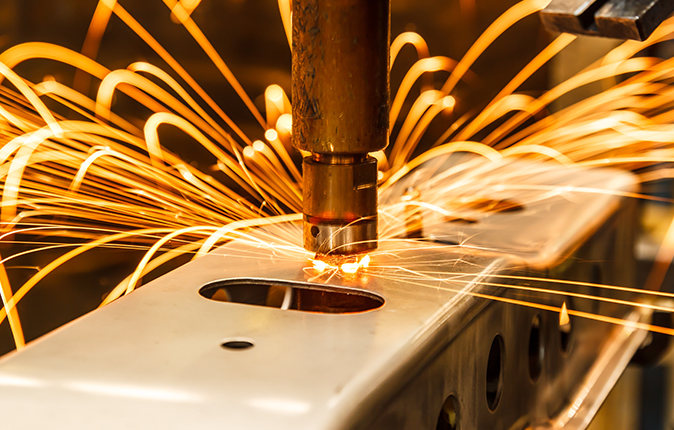

Welding, also known as fusion, is a manufacturing process and technology for joining metals or other thermoplastic materials such as plastics by heating, high temperature or high pressure.

Riveting, namely rivet connection, is a mechanical vocabulary. It is a method of connecting multiple parts by using axial force to thicken the nail rod pier in the part rivet hole and form a nail head.

Bonding is a method of firmly connecting the same or different materials with the help of the adhesive force generated by the adhesive on the solid surface.

When assembling key core parts, the assembler will scan the batch number of core parts with a code scanning gun, so as to ensure that all information of core parts (such as part number, name, manufacturer, production date, batch number, etc.) is bound. Subsequently, the above information of core parts can be queried through the information system.

Raw materials shall be subject to traceability inspection based on lot number / batch number to ensure the integrity of each chain of material manufacturers, dealers and agents.

In the manufacturing process, the operation process is standardized through the process flow card, and the production machines, operators and quantity are recorded to form a standardized work process. Make accounts, materials and cards consistent, provide real original basis for each processing process, and provide effective management support for production process control.

The assembly process adopts ERP, MES management system and code scanning technology, binds the batch number or work order number of each accessory, and effectively ensures the traceability of products through information management and process control.

Our products are distributed in more than 20 countries, and we have won high praises from many

worldwide famous big customers by our exquisite craftsmanship,high efficiency and excellent customer services.

A whole set of services from design, prototype, CNC machining, sheet metal & mould, painting, powder coating, assembly.

Strict quality control system, successfully obtained many international certifications: AS9100D,ISO9001, ISO14001, NADCAP. Achieve DPPM 500.

Advanced equipment, automated & intelligent production improve the quality and capacity: Germany DMG, US Haas CNC machines, Japan TSUGAMI lathe, Swiss ABB brand robot arm, ZEISS CMM.

10+ years experience and skillful engineers team, pursue excellence and innovation, improve efficiency and high-end product supply capacity. the fastest delivery within 3 days.