CNC Machining

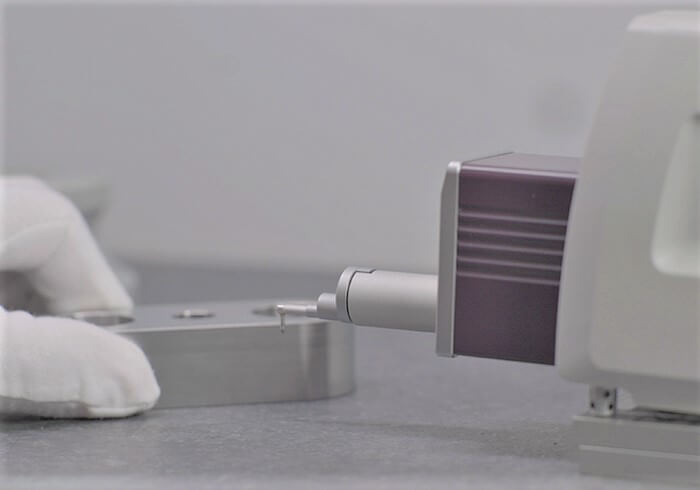

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

JM Precision has one full-automatic intelligent oxidation line and one manual oxidation line.

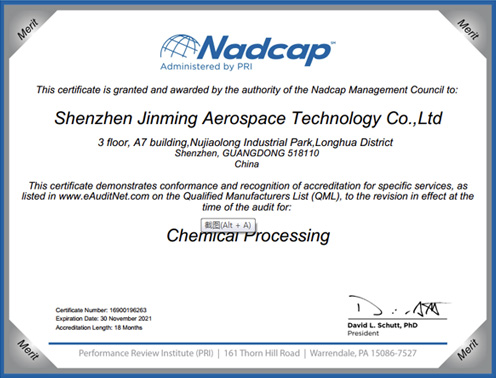

Get A quoteAdoptNADCAP Certification

JM Precision can provide sulfuric acid anodizing, phosphoric acid anodizing, harden anodizing, chemical oxidation, passivation, electroplating and other oxidation process types. It can customize the brightness and color according to customer needs, and can also do various decorative effects such as polishing, sand blasting, grinding, and so on.

Sulfuric

Acid Anodizing

Phosphoric

Acid Anodizing

Harden Anodizing

Chemical Conversion

Coatings

Passivation

Electroplate

Polishing

Sand Blasting

Grinding

Anodic oxidation is the electrochemical oxidation of metals or alloys. Aluminum and its alloys form a layer of oxide film on aluminum products (anode) under the action of external current under corresponding electrolyte and specific process conditions. Anodizing, if not specified, usually refers to sulfuric acid anodizing.

In order to overcome the defects of surface hardness and wear resistance of aluminum alloy, expand the scope of application and prolong the service life, surface treatment technology has become an indispensable part in the use of aluminum alloy, and anodic oxidation technology is the most widely used and successful.

Phosphoric acid anodizing refers to the reaction product film with good adhesion formed by chemical or electrochemical treatment of metal surface substances in material protection technology...

The anodic oxide film is generated by electrolysis with sulfuric acid, oxalic acid, chromic acid and phosphoric acid as electrolyte and aluminum workpiece as anode, which is mainly used for protection, decoration, electrical insulation, corrosion prevention, wear resistance No damage flaw detection and improve optical and thermal efficiency.

The main purpose of harden anodizing treatment of aluminum alloy is to improve various properties of aluminum and aluminum alloy, including corrosion resistance, wear resistance, weather resistance, insulation and adsorption. It is not only suitable for deformed aluminum alloy, but also for die-casting aluminum alloy parts.

Chemical oxidation refers to the process of using chemical oxidants to convert pollutants into stable, low toxic or non-toxic substances.

Common oxidants include ozone, hydrogen peroxide, hypochlorite, chlorine, chlorine dioxide, potassium permanganate and Fenton reagent. Sodium carbonate solution with chromate, silicate and phosphate is generally used for aluminum and aluminum alloy, caustic soda solution with oxidant is used for copper and copper alloy, and caustic soda solution with nitrate is used for carbon steel.

Passivation refers to the process of passivation in which the metal is oxidized by strong oxidant or electrochemical method to make the surface inactive. It is a method to change the metal surface into a state that is not easy to be oxidized and delay the corrosion rate of the metal.

In addition, an active metal or alloy, in which the chemical activity is greatly reduced and becomes a precious metal state, also known as passivation.

Electroplating is a process of plating a thin layer of other metals or alloys on some metal surfaces by using the principle of electrolysis. It is a process of using electrolysis to attach a metal film to the surface of metal or other material parts, so as to prevent metal oxidation (such as rust), improve wear resistance, conductivity, reflection, corrosion resistance (copper sulfate, etc.) and enhance beauty.

Polishing refers to the processing method of reducing the surface roughness of the workpiece by mechanical, chemical or electrochemical action to obtain a bright and flat surface.

It is the modification of the workpiece surface with polishing tools, abrasive particles or other polishing media.

Sand blasting process uses compressed air as the power to form a high-speed jet beam to spray the sprayed material to the surface of the workpiece to be treated at high speed, so as to change the appearance of the outer surface of the workpiece. Due to the impact and cutting effect of the abrasive on the workpiece surface, the workpiece surface can obtain certain cleanliness and different roughness, and the mechanical properties of the workpiece surface can be improved.

Grinding is a surface treatment method to form lines on the workpiece surface by grinding products and play a decorative effect. Because the surface wire drawing treatment can reflect the texture of metal materials, it has been loved by more and more users and widely used.

The anodizing process generally comes in 6 steps as shown below

Pre-treatment

Alkali etching & chemical polishing

Formation of anodic films

Dyeing

Sealing

Drying

JM Precision’s anodizing process has passed National Aerospace and Defense Contractors Accreditation Program (abbreviation:NADCAP), which enables it to provide customers with high quality service.

It is a special process certification project in the aviation industry. It evaluates the process compliance of suppliers involved in special processes in the aviation supply chain through the operation mode of industry management.

NADCAP certification mainly involves heat treating, chemical processing, welding,nondestructive testing, composites, coatings, materials testing, non-conventional machining, shot blasting, conventional machining as a special process, sealants, elastic seal, fluid distribution system, measurement and inspection, etc.

At present, more than 50 world-renowned aviation manufactures including Boeing, Airbus, COMAC, GE, Rolls-Royce, Safran, UTC, Honeywell have joined and participated in the NADCAP project. Obtaining NADCAP certification has also become the entry threshold for opening the aviation market and entering the aviation supply chain.

PR is the only administrative party of NADCAP project in the world and is responsible for the daily operation and management of NADCAP project. All technical links of NADCAP certification, from the formulation of audit criteria and project operation.

·In order to ensure the stability of aluminum alloy anodizing production process, it is necessary to test the current, voltage, pH value, conductivity, temperature, time, concentration and suspended impurities of each tank liquid.

·In order to ensure that the anodized oxide film of aluminum alloy meets the requirements, various performance tests need to be done, including Oxford film thickness test, Taber wear resistance test (hard anodizing), salt spray test, constant temperature and humidity test, color difference test, gloss test, color matching of standard light source, etc.

·All tests can meet ASTM B117 & ISO standards, or customized tests can be carried out according to customer standards.

The constant temperature & humidity tester is used to test various performance indexes of parts and materials of electronic and electrical engineering, automobile and motorcycle, aerospace, rubber, plastic, metal, colleges and universities, scientific research institutions and other related products under the condition of high temperature and constant temperature change.

Salt spray tester is mainly used for corrosion test in electronic and electrical industry, University Quality Inspection Institute, aerospace and other units. It is suitable for salt spray corrosion test of parts, electronic hardware components, protective layers of metal materials and industrial products. Our products can pass 350 hours of salt spray corrosion test according to standards.

We have obtained NADCAP certification, and have professional quality management team and various advanced high-precision testing equipment, the product quality is guaranteed.

We have one full-automatic intelligent oxidation line and one manual oxidation line, and the on-time delivery rate is 99%.

The brightness and color can be customized according to customer needs

We have rich process types: sulfuric acid anodizing, phosphoric acid anodizing, harden oxidation, chemical oxidation, passivation, electroplating and other oxidation process types , as well as various decorative effects such as polishing, sand blasting and grinding.

JM Precision can provide a variety of oxidation processes, and can customize the thickness, brightness and color of the oxide layer according to the specific needs of end customers.

For processes with high surface treatment difficulty and high requirements for color, appearance and test, we can implement them in strict accordance with the standards and provide high-quality surface treatment services.

The following processing cases are for your reference. If you have any questions or needs, Feel free to contact us.

| Part | Size | Application | Machining Process Used | Chemical Processing | Specific Feature |

|---|---|---|---|---|---|

| Bearing arm | 436.3*283.9*25.4mm | Aircraft seat | Al-alloy 7075-T651 | Sandblasting + natural color conductivity |

The inner wall is thin and easy to deform |

| Bracket | 925*416*36mm | Aircraft cabin | Al-alloy 2024-T351 | Hard anodizing |

Large area 2024 aluminum alloy is easily burned by hard anodizing |

| Shell | 160.8*96.7*10.4mm | Aircraft cabin | Al-alloy 2024-T351 |

Natural color conductive + hard anode |

When the two processes are applied to the same part, the surface treatment is more difficult |

| Decorative mask | 227.6*96.7*10.4mm | Aircraft cabin | Al-alloy 2024-T351 | Rose Gold anode oxidation |

Nickel free closure, in line with EU reach requirements. High color and appearance requirements |

| Rotating guide shaft | 66*Φ6.325mm | SUS 303 | Stainless steel passivation |

Parts need hydrogen embrittlement release |

|

| Guard plate | 150*123*1.5mm | Notebook computer | Al-alloy 7075-T651 | Black anodizing |

Foggy black, a customer part high test and appearance requirements |

|

5g microwave transmitting box |

283.8*16.5*23mm | communication | Al-alloy 6061-T651 | Black anodizing |

There are many blind holes and high appearance requirements |

Our products are distributed in more than 20 countries, and we have won high praises from many

worldwide famous big customers by our exquisite craftsmanship, high efficiency and excellent customer services.

A whole set of services from design, prototype, CNC machining, sheet metal & mould, painting, powder coating, assembly.

Strict quality control system, successfully obtained many international certifications: AS9100D,ISO9001, ISO14001, NADCAP. Achieve DPPM 500.

10+ years experience and skillful engineers team, pursue excellence and innovation, improve efficiency and high-end product supply capacity. the fastest delivery within 3 days.

of equipment and complete processes: there are three-axis, four axis and five axis machining centers, CNC lathe and turn milling compound, covering the whole process of turning, drilling, milling, drawing, grinding, EDM and so onThere are various types of equipment and complete processes: there are three-axis, four axis and five axis machining centers, CNC lathe and turn milling compound, covering the whole process of turning, drilling, milling, drawing, grinding, EDM and so on