CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

JM Precision has 2 sets of painting equipment and 3 sets of powder coating equipment

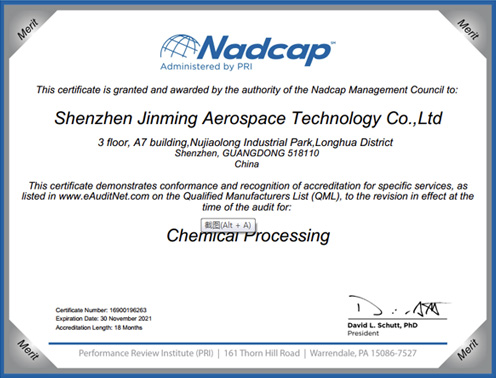

Get A quoteAdopt NADCAP Certification

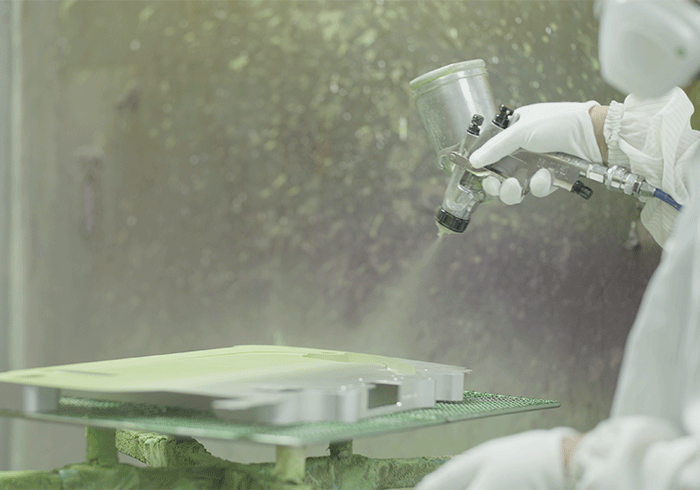

In JM Precision 10,000 grade dust-free workshop, keep constant temperature, humidity and clean air for a long time (air dust content < 10mg / M) ³) We have 2 sets of painting equipment and 3 sets of powder coating equipment, which are manually sprayed by our experienced and skilled spraying masters to ensure product quality and meet customer needs.

Paint Spraying

Powder Spraying

A method of dispersing uniform and fine droplets into the surface of the coated object through the spray gun with the help of air pressure. Usually, the spray gun is evenly sprayed on the surface of the object, which is water-resistant, oil-resistant and fast drying. It is used to paint cars, aircraft, wood, leather, etc.

In JM Precision 10,000 grade dust-free workshop, there are 2 sets of painting equipment. The painting equipment is flexible and can spray 360 ° without dead angle. It is manually sprayed by our experienced and skilled spraying masters to ensure product quality and meet customer needs. It is applicable to all kinds of metal processing parts and plastic processing parts, from CNC processing / sheet metal processing to painting processing, and we provide one-stop service.

The powder coating is sprayed on the surface of the workpiece with electrostatic powder spraying equipment. Under the action of static electricity, the powder will be evenly adsorbed on the surface of the workpiece to form a powder coating; After high temperature baking, leveling and curing, the powder coating becomes the final coating with different effects.

In JM Precision 10,000 grade dust-free workshop, we have 3 sets of powder coating equipment, which adopts imported low-pressure high atomization spray gun and is sprayed manually by experienced and skilled powder spraying masters. The spraying quality is stable and can meet various customized needs of customers.

The painting process normally comes in 4 steps as listed below

Pre-cleaning

Electrostatic de-dust process

Painting or Powder coating

Curing

JM Precision’s anodizing process has passed National Aerospace and Defense Contractors Accreditation Program (abbreviation:NADCAP), which enables it to provide customers with high quality service.

It is a special process certification project in the aviation industry. It evaluates the process compliance of suppliers involved in special processes in the aviation supply chain through the operation mode of industry management.

NADCAP certification mainly involves heat treating, chemical processing, welding,nondestructive testing, composites, coatings, materials testing, non-conventional machining, shot blasting, conventional machining as a special process, sealants, elastic seal, fluid distribution system, measurement and inspection, etc.

At present, more than 50 world-renowned aviation manufactures including Boeing, Airbus, COMAC, GE, Rolls-Royce, Safran, UTC, Honeywell have joined and participated in the NADCAP project. Obtaining NADCAP certification has also become the entry threshold for opening the aviation market and entering the aviation supply chain.

PR is the only administrative party of NADCAP project in the world and is responsible for the daily operation and management of NADCAP project. All technical links of NADCAP certification, from the formulation of audit criteria and project operation.

·In order to ensure the correct use of paint, it is necessary to manage the validity period of paint and powder; moreover, control the temperature and humidity of paint and powder warehouse is also needed;

·Kept 10,000 grade dust-free condition in painting workshop.

·In order to ensure the stability of the production process, the operation method of each coating shall be carried out according to the requirements of TDS documents, and the relevant parameters of each process shall be recorded in real time.

·In order to ensure that the sprayed film meets the requirements, relevant performance tests need to be done, such as Oxford film thickness test, hardness test (meeting ISO15184 & ASTM D 3363), adhesion test (meeting ISO2409), adhesion test (meeting ISO2431), impact test (meeting ISO6272-1), color difference test, gloss test and color matching of standard light source.

·All tests can meet ASTM B117 & ISO standards, or customized tests can be carried out according to customer standards.

Using the eddy current measurement principle, it can easily and nondestructive measure the paint, plastic, rubber and other coatings on non-ferrous metal substrates, or the thickness of anodic oxide film on aluminum substrates. It is widely used in machinery, automobile, shipbuilding,chemical industry, electroplating, plastic spraying, enamel, plastics and other industries.

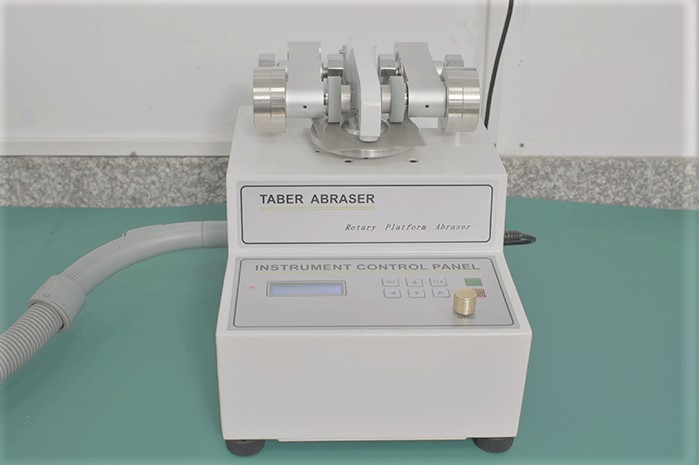

It is used to measure the wear resistance of materials, expressed by wear amount or wear index. Wear resistance is related to almost all properties of materials, and under different wear mechanism conditions, there are different requirements for material properties in order to improve wear resistance.

It is widely used in the field of color management in plastic, printing, paint ink, textile and garment industries. According to the lab and LCH principles of CIE color space, the measurement shows the color difference △ E and △ lab values between the sample and the measured sample.

It is an instrument used to measure the surface gloss of ceramics, paints, inks, plastics, marble, aluminum, hardware and other materials.

We have obtained NADCAP certification, and have professional quality management team and various advanced high-precision testing equipment, the product quality is guaranteed.

The spraying workshop shall strictly abide by the relevant management regulations of the dust-free workshop, and regularly monitor to ensure that the workplace is 10,000 grade dust-free.

We have 2 sets of painting equipment and 3 sets of powder coating equipment, with a delivery rate of 99%.

JM Precision can provide painting and powder spraying processes, and can customize the thickness, brightness and color of the spraying layer according to the specific needs of end customers. For processes with high surface treatment difficulty and high color and appearance requirements, we can implement them in strict accordance with the standards and provide high-quality surface treatment services. The following processing cases are for your reference. If you have any comments and needs, Feel free to contact us.

| Part | Size | Application | Material | Chemical processing | Specific Feature |

|---|---|---|---|---|---|

| Shell | 556*328*5mm | Aircraft cabin | Al-alloy 7075-T651 |

Natural color conductive+primer+color paint+finish |

The parts have a large area and are locally sprayed with three layers of different paints, with high requirements for color and appearance |

| Fixed plate | 623.5*365.8*5mm | Aircraft cabin | Al-alloy 7075-T651 |

Natural color conductive+powder spraying |

Large part area,flat powder, high appearance requirements |

| Seat bracket | 521.3*312.9*5mm | Aircraft seat | Al-alloy 6061-T651 |

Phosphoric acid anodizing+3M primer |

Surface treatment before bonding (anodizing and spraying) |

| Trim panel | 365.9*215.6*2mm | Aircraft cabin | Al-alloy 2024-T351 | Natural color anode (not sealed)+primer |

It is not closed after anodizing, and spraying treatment needs to be carried out within 24 hours |

Our products are distributed in more than 20 countries, and we have won high praises from many

worldwide famous big customers by our exquisite craftsmanship, high efficiency and excellent customer services.

A whole set of services from design, prototype, CNC machining, sheet metal & mould, painting, powder coating, assembly.

Strict quality control system, successfully obtained many international certifications: AS9100D,ISO9001, ISO14001, NADCAP. Achieve DPPM 500.

Advanced equipment, automated & intelligent production improve the quality and capacity: Germany DMG, US Haas CNC machines, Japan TSUGAMI lathe, Swiss ABB brand robot arm, ZEISS CMM.

10+ years experience and skillful engineers team, pursue excellence and innovation, improve efficiency and high-end product supply capacity. the fastest delivery within 3 days.