CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

MISSION

VISION

Key Figures

Mr. Luo Hengsong

Mr. Ding Wenyong

Team Introduction

R & D Team

Quality Team

Factory / Workshop Display

Assembly Drawing

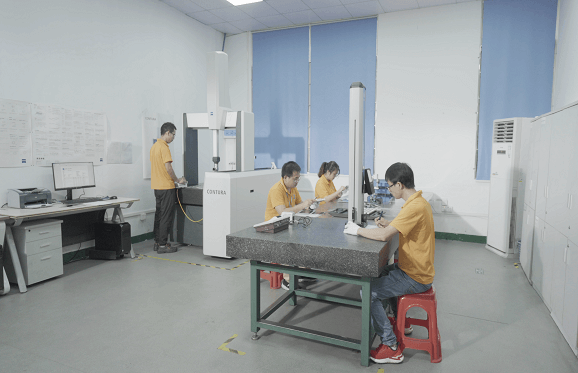

Measuring Room

Meeting Room

Office Map

Oxidation Workshop

CNC Workshop

Sheet Metal Workshop

Painting Workshop

Training Room

Our products are distributed in more than 20 countries, and we have won high praises from many

worldwide famous big customers by our exquisite craftsmanship, high efficiency and excellent customer services.

A whole set of services from design, prototype, CNC machining, sheet metal & mould, painting, powder coating, assembly.

Strict quality control system, Achieve DPPM 500.

Successfully obtained many international certifications:

AS9100D,ISO9001, ISO14001, NADCAP .

Advanced equipment: Germany DMG, US Haas CNC machines,

Japanese TSUGAMI lathe, Swiss ABB brand robot arm, ZEISS CMM.

Automated & intelligent production improve the quality and capacity.

10+ years experience and skillful engineers team,

pursue excellence and innovation,

improve efficiency and high-end product supply capacity.

The fastest delivery within 3 days.

Certificate Of Honor

Certificate of Quality

ISO14001

AS9100D & ISO9001

NADCAP

Invention Patent

Patent Certificate

Intellectual Property Management System Certification

Utility Model Patent

Invention Patent

Invention Patent

Invention Patent

High Tech Enterprise

Top 100 Foreign Trade Enterprises

Customer Trophy

Winner Supplier

Winner Supplier Award

Supplier Partner Award

Excellent Support Award

Supplier Excellence Award

Dun & Bradstreet Certified

Our Partner