CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

CNC machining is widely used in the aerospace, automotive, medical, electronics, construction, and other industries. Then choosing a good high precision CNC machining manufacturer is crucial for every industry.

High precision CNC machining is a process that uses computer-controlled machines to produce parts with high accuracy and quality. CNC machining can be used for various materials, such as metal, plastic, wood, and composite.

If you are looking for an excellent high precision CNC machining manufacturer for your project, then please read this list of the top 6 high precision CNC machining manufacturers; it will give you the answer you want.

Introduction:

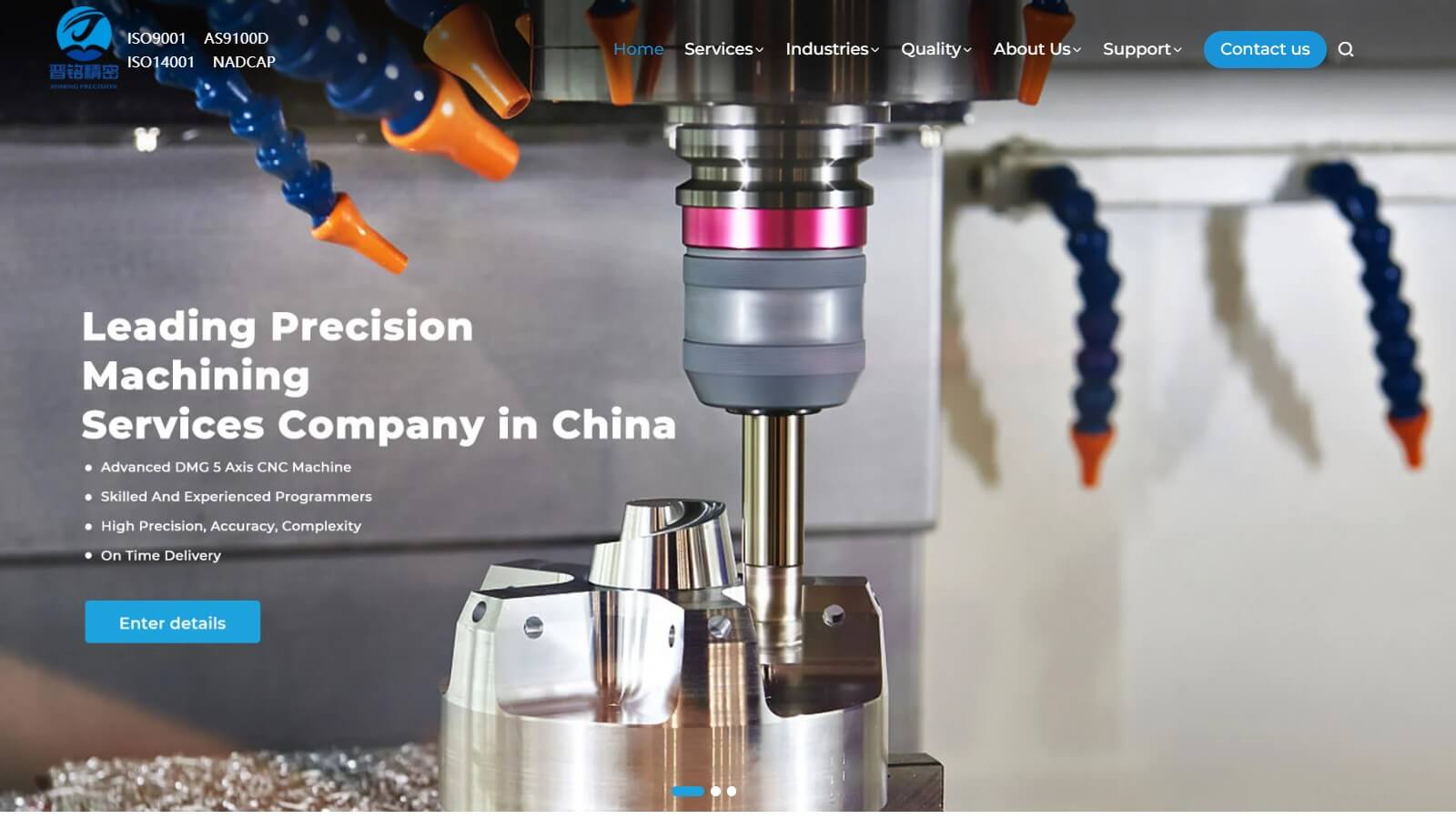

JM Precision is a high-precision processing manufacturer from Shenzhen, China. After years of development, JM Precision now has a production site with a total area of more than 300,000 square feet, production equipment worth more than US$15 million, and an annual production capacity of more than US$65 million. They have three core competitiveness factors to continuously create value for customers and their industry: strong engineering research and development capabilities, impeccable manufacturing capabilities, and fast customer service.

Advantages:

Video:

Introduction:

CRP Meccanica is a CNC machining company devoted to high-precision CNC machining for motorsports, automotive, and other demanding fields. Due to its knowledge, CRP Meccanica is able to provide reliable services at a good value.

Advantages:

Video:

Introduction:

Founded in 1919 by Sadakichi Yamazaki, Mazak is a leading manufacturer of machine tools and laser systems worldwide. The company specializes in a wide range of CNC-related products, including lathes, lathe-mill cutting centers, vertical and horizontal machining centers, CNC laser systems,FMS flexible production systems,CAD/CAM systems,CNC devices,and production support software. Mazak's products are highly recognized in the industry for their precision and high speed and are extensively used across various industries, including automobiles,machinery,electronics,energy,and medical.

Advantages:

Video:

Introduction:

At Reading Plastic & Metal, they produce your parts with precision, accuracy, and repeatability to ensure high-precision CNC milling. Their team uses computer-driven CNC mills to create advanced plastic parts to tolerances of +/-.001 and a 15-RA surface finish. A second post-milling operation saves you time and reduces production costs. they can add threads, finish through holes, mounting surfaces and brand parts by hot stamping or silk printing. they also machine any associated metal parts required for your design.

Advantages:

Video:

Introduction:

Panek Precision is a CNC machining manufacturer founded in 1945 by Chester Panek in a small Chicago factory with a track record of continued steady growth. They remain family-owned and operated under their current president, Gregg Panek. In April 2006, they moved into our fifth facility, a modern 106,000-square-foot manufacturing facility in Northbrook, IL.

Advantages:

Video:

Introduction:

Founded in 1923 by Christian Trumpf in Stuttgart,Germany, TRUMPF is a global leader in technology and market share in the industrial laser and laser system industry. The company also produces various types of machine tools,such as laser cutting machines,punching machines,bending machines,welding robots,laser welding equipment,laser tube cutting machines,printing systems,3D printing systems,punching laser machines,material storage systems,and automation devices.TRUMPF's products are widely used in various industries,such as automotive,aerospace,electronics, medical, and construction equipment.

Advantages:

Video:

All in all, these manufacturers introduced have strong high-precision CNC machining capabilities; if you want to know other information, please contact us.