CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

Precision machining is critical in the aerospace industry. It is used to make parts for aircraft engines, landing gear and fuselages. So let’s learn about the secrets of precision machining and gain more knowledge.

• What is precision machining?

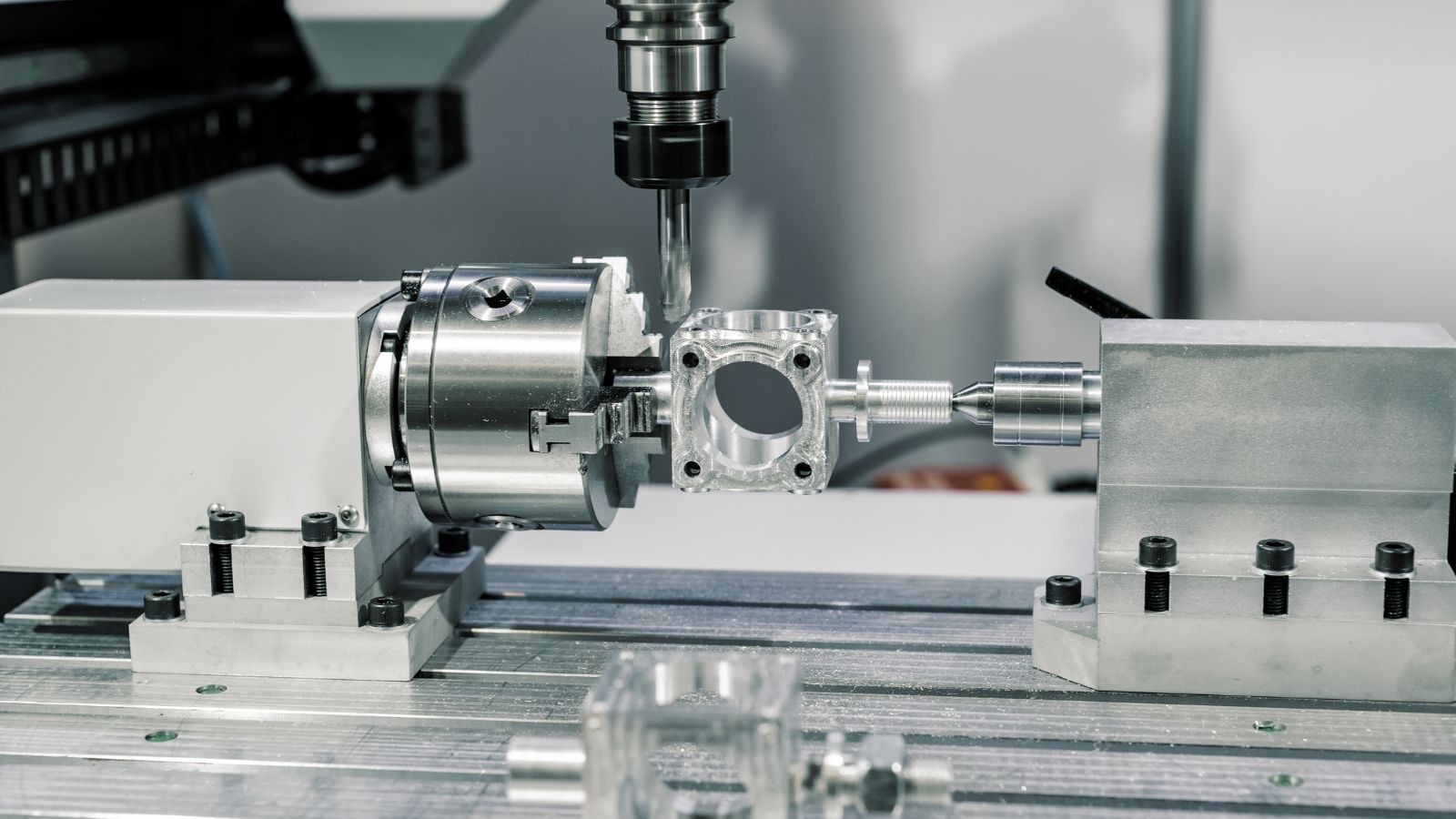

Precision machining is a process that uses tools to remove material from a workpiece to create a part with a specified shape, size, and tolerance. The tools used in precision machining are typically very sharp and precise, and the machines used are often computer-controlled.

• Precision machining processes

There are many different precision machining processes available, each with its own advantages and disadvantages. Some of the most common precision machining processes include:

CNC machining: CNC machining is a computer-controlled process that uses a cutting tool to remove material from a workpiece. CNC machining is a very versatile process that can be used to produce a wide variety of parts.

Grinding: Grinding is a process that uses abrasive particles to remove material from a workpiece. Grinding can produce very smooth and accurate surfaces.

Turning: Turning is a process that uses a lathe to rotate a workpiece while a cutting tool is used to remove material. Turning is a versatile process that can be used to produce a wide variety of cylindrical parts.

Milling: Milling is a process that uses a milling cutter to remove material from a workpiece. Milling can be used to produce a wide variety of shapes and features.

Electrical discharge machining (EDM): EDM is a process that uses an electric spark to remove material from a workpiece. EDM is a very precise process that can be used to produce very small features.

Aerospace

Precision processing is essential in the aerospace industry. It is used to create parts for aircraft engines, landing gear, and fuselage. For example, precision processing is used to create the blades of a jet engine, which must be very precise in order to operate efficiently.

Automotive

Precision processing is also used in the automotive industry. It is used to create parts for engines, transmissions, and brakes. For example, precision processing is used to create the gears and bearings that allow the engine to turn the wheels.

Medical

Precision processing is also used in the medical industry. It is used to create parts for implants, surgical instruments, and diagnostic equipment. For example, precision processing is used to create the implants that are used to replace damaged or missing bones.

Manufacturing

Precision processing is used in a wide variety of manufactured goods, such as electronics, appliances, and machinery. For example, precision processing is used to create the components that are used to assemble electronic devices.

Precision machining is a manufacturing process that uses machines to remove material from a workpiece to create a part with a specified shape, size, and tolerance. Precision machining is used in a wide variety of industries, including aerospace, automotive, medical, and manufacturing.

• Metals: Metals are the most common materials used in precision machining. They have good strength, hardness, and corrosion resistance. Common metals include steel, aluminum, stainless steel, titanium, and nickel.

• Plastics: Plastics are lightweight, strong, and easy to machine. Common plastics used in precision machining include nylon, polycarbonate, and PTFE.

• Ceramics: Ceramics are hard, wear-resistant, and corrosion-resistant materials. Common ceramics used in precision machining include alumina, silicon carbide, and silicon nitride.

• Composite materials: Composite materials are made up of two or more materials. They have unique properties that make them suitable for a variety of applications. Common composite materials used in precision machining include carbon fiber, fiberglass, and aluminum alloy.

Precision machining is a manufacturing process that uses machines to remove material from a workpiece to create parts with specified shapes, dimensions, and tolerances. Precision machining has many advantages, including:

High precision: Precision machining can produce parts with very tight tolerances. This is important for parts that must fit precisely (such as gears and bearings).

Smooth Surface: Produce parts with very smooth surfaces. This is important for parts that must be sealed or must slide against each other.

Complex shapes and features: Precision machining can produce parts with complex shapes and features. This is important for parts that require special design.

• The type of parts you need.

Not all precision machining companies are created equal. Some companies specialize in a particular type of part, such as gears, bearings, or medical implants. It is important to find a company that has experience with the type of parts you need.

• The precision and tolerances required.

Precision machining can produce parts with very tight tolerances. It is important to specify the precision and tolerances required for your parts.

• The materials you need.

Precision machining can be used to machine a variety of materials, including metals, plastics, and ceramics. It is important to specify the material you need for your parts.

• The quantity of parts you need.

Some precision machining companies specialize in small-batch production, while others specialize in mass production. It is important to specify the quantity of parts you need.

In summary, precision machining is a manufacturing process that uses machines to remove material from a workpiece to create parts with specific shapes, sizes, and tolerances. Precision machining offers many advantages, including high accuracy, smooth surfaces, complex shapes and repeatability.