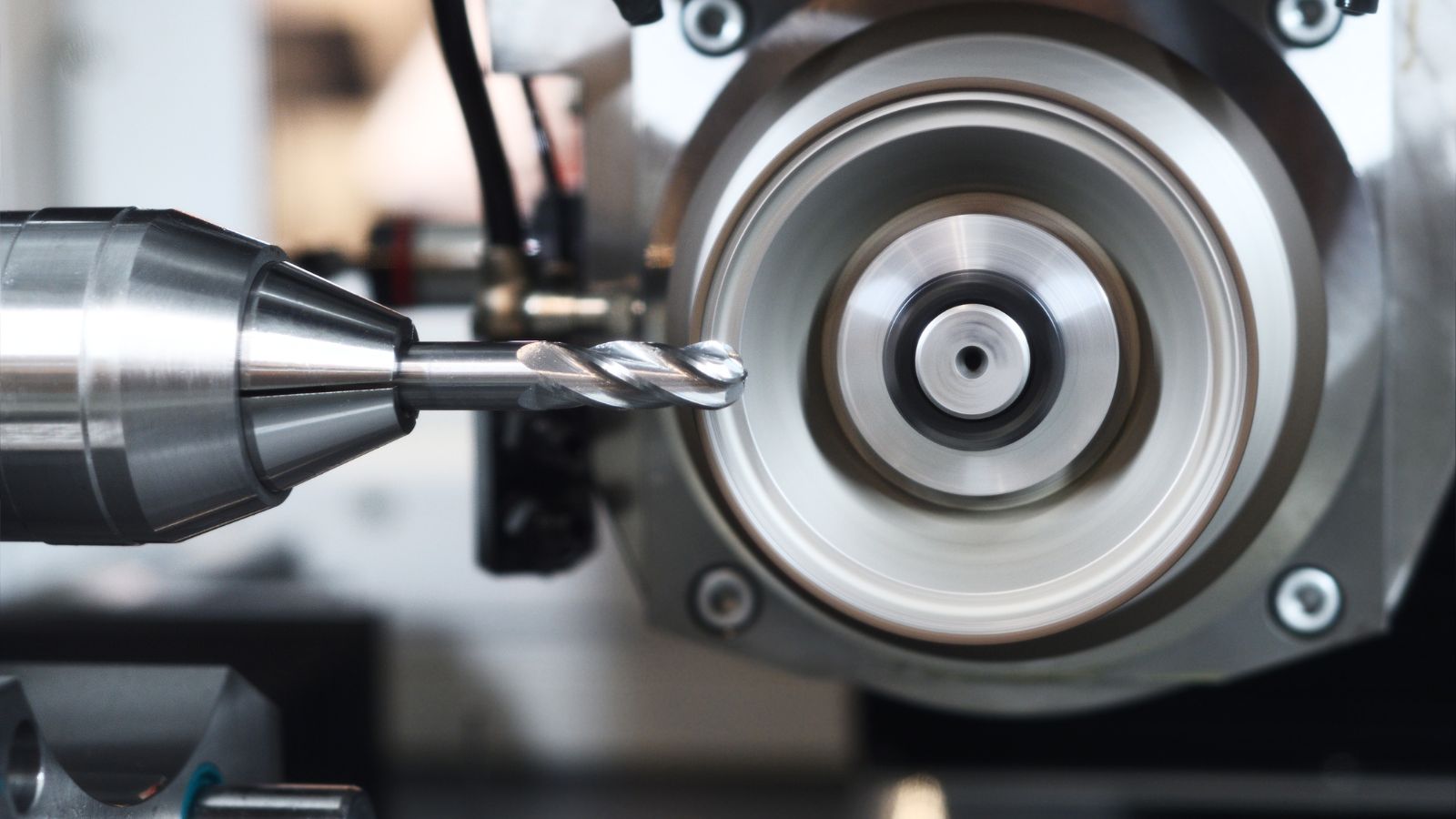

CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

In precision machining, cleaning is one of the most important steps, because it will greatly affect the dimensional accuracy, surface quality, service life, etc. of the product. Therefore, in precision machining, maintaining cleanliness is an important measure to ensure product quality and production efficiency.

Cleaning plays a vital role in precision machining. Maintaining a clean production environment helps reduce uncertainty caused by external factors and ensures the purity of materials and tools. During processing, any tiny impurities or particles can have a negative impact on the quality of the finished product. Therefore, cleaning in precision machining is not just a practice, but a critical factor in ensuring products meet specifications.

In the process of precision machining, especially high-intensity operations such as high-speed cutting and grinding, impurities and particles are more likely to have a negative impact on the product. Therefore, these potential hazards can be reduced by using appropriate cleaning measures, such as using high-efficiency filtration systems, regularly cleaning equipment, and keeping work areas tidy.

Maintaining cleanliness in precision machining is not only about avoiding negative effects, but also about realizing a range of significant advantages and benefits. First, cleaning in precision machining helps improve product accuracy and consistency. By reducing the presence of impurities and particles, manufacturers can more precisely control the processing process, ensuring the final product meets design specifications.

Additionally, cleaning can extend the life of your tools. In a clean production environment, tools are less susceptible to damage from impurities and particles, so they stay sharp and productive longer. This not only reduces production costs, but also improves production efficiency.

Staying Clean also aligns with environmental regulations and sustainability goals, allowing manufacturers to reduce environmental impact while complying with regulations.

Conclusion

By taking effective cleaning measures, contaminants can be effectively controlled to ensure the quality and performance of precision machined products. For enterprises, this can not only ensure product quality, but also save product losses.

If you have any other questions, please contact us and we will have experts to provide services for you!