CNC Machining

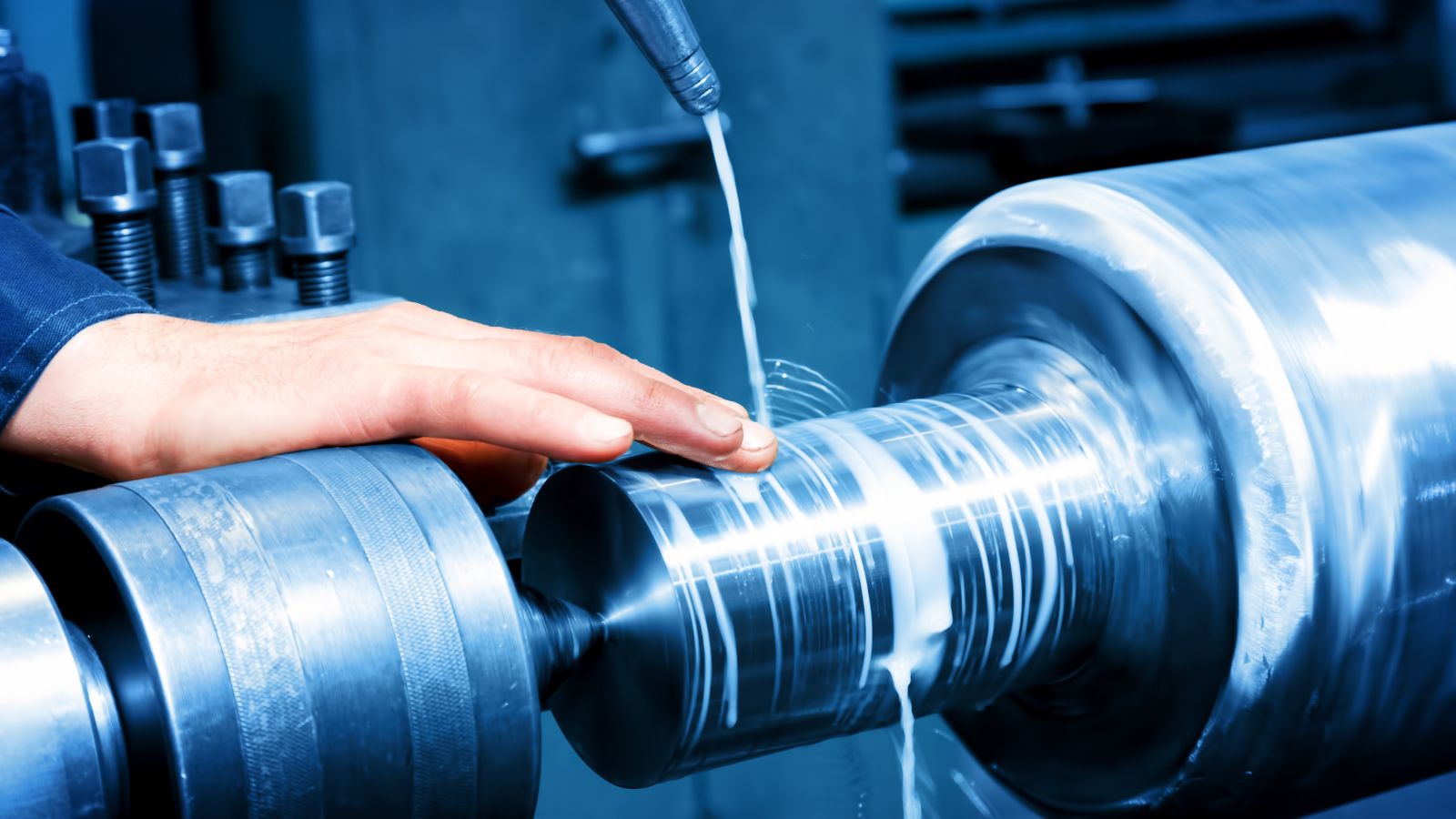

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

CNC precision machining is a manufacturing process that uses computer numerical control (CNC) machines to remove material from a block of raw material, creating custom parts with high precision and accuracy.

The hourly cost of CNC machining depends on a variety of factors, including: the type and configuration of the machine, the material being machined, the complexity of the machining, the volume of machining, and geographic location.

Generally speaking, CNC machining costs between $10 and $100 per hour. Taking average machining costs in the United States as an example, the hourly cost of CNC machining typically ranges from $20 to $50.

2. What is The Precision of CNC Machining?

The accuracy of CNC machining refers to the deviation of the size and shape of the part from the design drawing. CNC machining can achieve extremely high accuracy, typically +/- 0.001 inches or better. This is much higher than traditional machining methods. The accuracy of CNC machining depends on a variety of factors, including the type and configuration of the machine, the material being processed, its complexity, quantity, etc.

The main reasons why CNC services are expensive include the high cost of mechanical equipment, high technical requirements, high processing precision, and the need for high-quality materials and equipment.

| Build CNC | Pros | The cost is lower, especially if you have your own manufacturing tools and equipment. Machines can be customized to your specific needs. Gain greater control and flexibility. |

|---|---|---|

| Cons | Certain technical knowledge and skills are required. Errors can occur, causing damage to the machine or producing substandard parts. | |

| Buy CNC | Pros | Higher accuracy and reliability can be achieved. No repairs or maintenance required. |

| Cons | higher cost. May not meet your specific needs. |

CNC machining is a technology-intensive industry. To make money successfully, you need to have certain technical knowledge and skills. You also need to understand market needs and be able to provide a high-quality product or service. Establishing good customer relationships, continuous learning and innovation, and having certain local resources are indispensable. If you meet these conditions, you might as well try to join this industry to make money!

High Cost: CNC machines often cost tens or even hundreds of thousands of dollars. This makes them potentially unaffordable for small businesses or individuals.

Complexity: Requires a skilled operator to use. This makes them potentially difficult to learn and use for those without training.

Precision Requirements: CNC machines need to operate at high precision to produce high-quality products. This makes them highly demanding for machining complex parts or achieving extremely high precision.

Take a specific actual example:

• A typical three-axis CNC lathe costs about $100,000.

• A five-axis CNC machining center costs about $500,000.

• Becoming a CNC operator requires at least one year of training and costs approximately $20,000.

Typically, five-axis CNC machines cost between $100,000 and $1 million. In the United States, five-axis CNC machines typically cost between $200,000 and $500,000. , depending on a variety of factors such as the size, brand, and features of the machine.

Here are some specific details:

Price range: The price range is quite wide. Prices start at around $80,000 on the low end and can exceed $500,000 on the high end. There are also machines priced around $105,000 to $110,000, which seems to be a mid-range option.

Factors affecting price:

Machine size: Larger machines that can handle larger workpieces tend to cost more.

Brand: Well-known brands may charge higher prices for their machines due to reputation and quality assurance.

Function: Machines with more complex functions, higher precision, and greater automation cost more.

Application: These machines are versatile and can be used in various industries such as aerospace, automotive, mold making, etc. They can cut and mill a variety of materials, including wood, plastic, foam, resin, and metals like aluminum and copper.