CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

CNC machining is a term that refers to a manufacturing process that uses computerized controls and machine tools to remove layers of material from a workpiece and produce a custom-designed part. CNC stands for computer numerical control, and it is a subtractive process, meaning that it creates the desired shape by cutting away excess material, unlike additive processes such as 3D printing.

CNC machining can be used for a wide range of materials, such as metals, plastics, wood, glass, foam, and composites, and it has applications in various industries that require high precision, accuracy, and cost-effectiveness. Some examples of CNC machining products are aerospace components, medical devices, automotive parts, and molds.

There are three main types of CNC machining processes: milling, turning, and drilling. Each one has its own advantages and disadvantages, depending on the shape, size, and complexity of the part to be made. Here is a brief overview of each process:

Milling: This is the most common type of CNC machining process. It involves the use of a rotary cutting tool, called a milling cutter, that moves along multiple axes to create different shapes and features on the workpiece. The milling cutter can have various shapes and sizes, depending on the desired outcome. Milling can create flat and curved surfaces, holes, slots, grooves, pockets, and more.

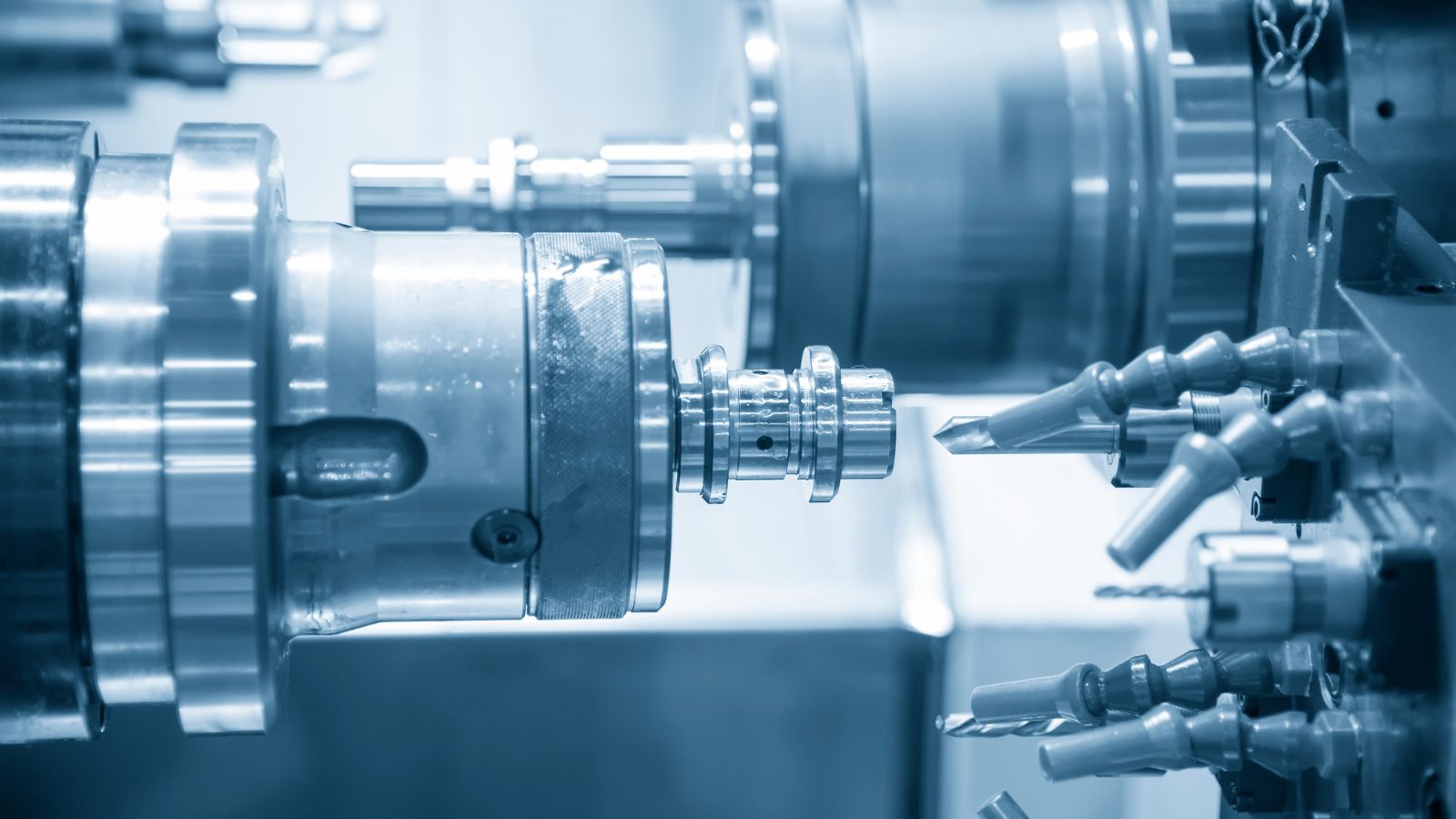

Turning: This is a CNC machining process that uses a single-point cutting tool to remove material from a rotating workpiece, called a lathe. The cutting tool moves along the length of the workpiece, creating cylindrical shapes and features. Turning can create external and internal features, such as threads, tapers, knurls, and more.

Drilling: Drilling is a machining process that uses a rotating drill bit to create holes in a workpiece. The drill bit can move along the surface of the workpiece or within the workpiece. Drilling can be used to create holes of various shapes and sizes.

CNC machining offers several advantages, including:

• High precision and repeatability: CNC machining can manufacture parts with high precision and repeatability. This is very important for manufacturing parts that require precision or for mass production of parts.

• High efficiency: CNC machining can improve manufacturing efficiency. This is important for shortening delivery times and reducing production costs.

• Flexibility: CNC machining can be used to manufacture parts of a variety of shapes and complexities. This makes it suitable for a variety of manufacturing applications.

CNC machining applications

CNC machining is widely used in a variety of manufacturing industries, including:

• Aerospace, car, medical, mechanical, electronic

CNC machining is one of the most important technologies in manufacturing. It can be used to manufacture parts of various shapes and complexities with high precision, repeatability and efficiency