CNC Machining

200 sets high precision CNC machine, covering turning, drilling, milling, broaching,grinding, wire EDM etc. all machining process.Machined prototypes and production parts in as fast as 1-3 days

Sheet metal is a comprehensive cold working process for sheet metal (usually less than 6mm), including shearing, punching/cutting/compounding, folding, riveting, splicing, forming (such as automobile body), etc. Its remarkable feature is that the thickness of the same part is the same.

JM Precision has complete sheet metal processing equipment: punch, bending machine, EDM, grinder, etc., covering plate cutting, stamping, laser cutting, crimping, bending, ironing, welding and other processing processes, which can meet customers' various sheet metal processing needs.

As a sophisticated aerospace sheet metal fabrication manufacturer in China providing custom sheet metal fabrication service, JM is capable to deliver the precision machined Aerospace components that customers need, our engineers, designers and operators are accomplished enough to give the engineering services and face the challenges from conception, design, to production and final Aerospace parts, offering the most cost-effective solution. Whether you need low-volume Aerospace parts prototypes or high-volume production, JM Precision can provide better surface quality, and higher consistent accuracy products in a faster production circle.

Our company has passed the ISO9001 quality management system certification, AS9100D aviation quality management system certification, ISO14001 environmental management system certification and a number of NADCAP special process certifications. With exquisite technology, high efficiency and excellent service, our company has won the praise of many international well-known customers in more than 20 countries all over the world.

● High Precision Equipment: We have advanced high-precision equipment like a German DMG 5-axis machine, and a US Haas 5-axis machine, with a tolerance down to +/-0.0004’’(0.01mm).

● Skillful Engineering Team: We have 10+ years of experience in a skillful engineering team, that pursues excellence and technical innovation.

● Automatic Intelligent Equipment: We have automatic intelligent equipment like the Swiss ABB robot arm which can save time and labor costs, thus improving efficiency.

In the production and manufacturing of aerospace products, JM Precision has the following capabilities:

● Stamping

It is a common sheet metal forming process. Punch and die groups are used to punch holes in sheet metal. During machining, the sheet metal is placed between the punch and the die, and then the punch is pressed down and passes through the sheet metal, thus completing the punching process.

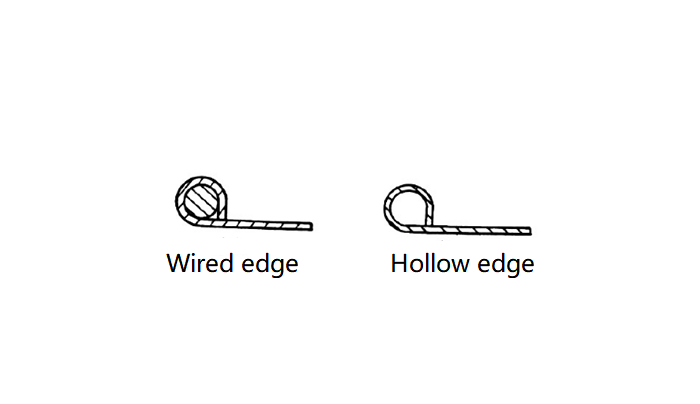

● Crimping

It is a sheet metal forming process. After the initial production of sheet metal, there are usually sharp edges with "burrs". The purpose of crimping is to smooth the sharp and rough sheet metal edges to meet the use requirements of the project.

It is a sheet metal forming process. After the initial production of sheet metal, there are usually sharp edges with "burrs". The purpose of crimping is to smooth the sharp and rough sheet metal edges to meet the use requirements of the project.

● Bending

It is another common sheet metal forming process. Manufacturers usually use brake presses or similar mechanical presses for metal bending. The sheet metal is placed on the die, and the punch is pressed down on the sheet metal. The huge pressure makes the sheet metal bend.

It is another common sheet metal forming process. Manufacturers usually use brake presses or similar mechanical presses for metal bending. The sheet metal is placed on the die, and the punch is pressed down on the sheet metal. The huge pressure makes the sheet metal bend.

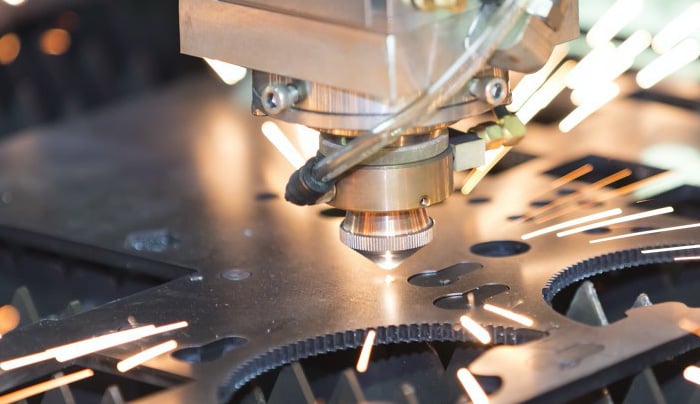

● Laser Cutting

Laser cutting has become a more and more common sheet metal forming process. When the sheet metal is exposed to high power and high density laser, the heat of the laser melts or vaporizes the sheet metal in contact with it, forming a cutting process. This is a faster and more accurate cutting method, which is automatically executed by a computer numerical control (CNC) laser cutting machine.

Sheet metal has the characteristics of lightweight, high strength, conductivity (can be used for electromagnetic shielding), low cost and good mass production performance.

It plays an important role in the construction and manufacturing industry. In the construction industry, it is used as a building and shell or roof; In the manufacturing industry, sheet metal has been widely used in electronic and electrical appliances, communication, the automobile industry, medical devices and other fields. For example, sheet metal is an essential part of computer chassis, mobile phones and MP3. With the more and more extensive application of sheet metal, the design of sheet metal parts has become a very important part of the process of product development.

Mechanical engineers must master the design skills of sheet metal parts so that the designed sheet metal can not only meet the requirements of product function and appearance but also make the manufacturing of stamping dies simple and low cost.

Sheet Metal Processing has a long list of available materials for prototypes and manufacturing parts, from hard metals like stainless steel and carbon steel to soft metals such as aluminum, copper, and brass.

● Aluminum

● Stainless steel

● Brass

● Bronze

● Copper

● Carbon Steel

No matter what, if you require aerospace sheet metal fabrication parts, we can help you with all your machining needs. Our advanced sheet metal fabrication capabilities enable us to take prototyping to small volume and medium-range projects as well as high volume repeat production.

Please click here to request a quote for hi-tech sheet metal fabrication in the aerospace industry or contact us at +86-755 2805 0226. Alternatively, you can also send us an email with your queries at enquiry@jmprecisionmfg.com today to know more about our sheet metal fabrication capabilities.